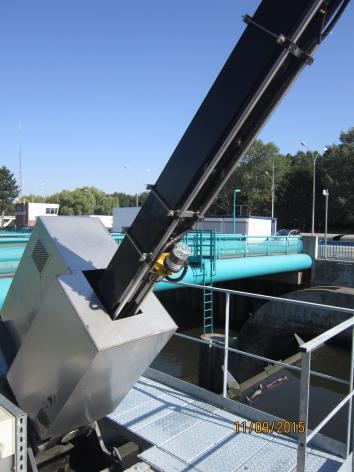

This case study focuses on the lubrication of ZIMM worm screws and the bevel gears of sluice gate flaps. These components are subjected to heavy loads and operate in temperatures ranging from -10°C to 40°C, exposed to various climatic conditions. The project was implemented for a major waterway management organization, highlighting the importance of maintaining these critical components efficiently.

Memolub® HPS

Automating Lubrication for worm screws and sluice gate gearboxes.

CONTEXT

PROBLEM

Manual lubrication was nearly impossible due to difficult access. Inadequate lubrication frequency, resulting from a lack of personnel, led to the breakdown of the bronze nut in the worm screw and the gears in the bevel gearbox. This caused significant mechanical failures and downtime.

SOLUTION

A Memolub HPS, with 240cc cartridge and a 4-outlet progressive distributor block, providing lubrication to two points on the worm screw and two points on the bevel gearbox was installed. The system was set to expel 2.4 cm³ of grease per day, with a frequency of lubrication every 6 hours, ensuring consistent and adequate lubrication. With this setting, the cartridge lasts for three months before needing replacement, using Castrol's Tribol 3020/1000-1 grease. This automated setup ensured reliable lubrication despite the challenging environmental conditions.

RESULTS

The implementation of the Memolub HPS system eliminated mechanical failures and reduced the risk of falls during manual lubrication tasks. Maintenance personnel experienced significant time savings, as the automated system ensured that lubrication was carried out regularly and effectively without the need for manual intervention. This solution proved highly effective in maintaining the optimal operation of the ZIMM worm screws and sluice gate gearboxes, enhancing their reliability and lifespan.