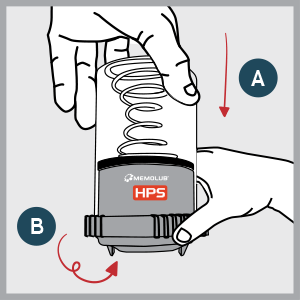

- Do not open the housing: loaded spring

- Hold MEMOLUB® down during manual checks

- Leq <70 dB

- Use MEMOLUB® only for greasing machinery

- Use only lubricant cartridges and batteries recommended by the manufacturer

Memolub® HPS KNOWLEDGE BASE

Dimensions

Standard

120cc I 4oz

Mega

240cc I 8.1oz

Giga

480cc I 16.2oz

OIL R-500

500cc I 16.9oz

Precautions

INSIDE THE BOX

MEMOLUB® HPS Pump

MEMOLUB® Housing Kit

MEMOLUB® HPS Memo Kit

Settings & Installation

FREQUENCY SETTINGS

| MEMO COLOR COMBINATION | DOSING PERIODICITY | MAX. DAILY OUTPUT* | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (120CC) | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (240CC) | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (480CC) |

|---|---|---|---|---|---|

|

|

1 hour | 14.4 cm3/day | 0.25 month | 0.5 month | 1 month |

|

|

2 hours | 7.2 cm³/day | 0.5 month | 1 month | 2 months |

|

|

6 hours | 2.4 cm³/day | 1.5 months | 3 months | 6 months |

|

|

12 hours | 1.2 cm³/day | 3 months | 6 months | 12 months |

|

|

18 hours | 0.9 cm³/day | 4 months | 8 months | 16 months |

|

|

24 hours | 0.6 cm³/day | 6 months | 12 months | - |

|

|

48 hours | 0.3 cm³/day | 12 months | - | |

*Maximum daily output without stroke washers.

VOLUME SETTINGS [cc/day]

| NUMBER OF STROKE WASHERS* | MEMO RINGS COMBINATION | ||||||

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

| 14.4 cm³ | 7.2 cm³ | 2.4 cm³ | 1.2 cm³ | 0.9 cm³ | 0.6 cm³ | 0.3 cm³ | |

|

13.5 cm³ | 6.75 cm³ | 2.25 cm³ | 1.13 cm³ | 0.84 cm³ | 0.56 cm³ | 0.28 cm³ |

+ +

|

12.6 cm³ | 6.3 cm³ | 2.1 cm³ | 1.05 cm³ | 0.79 cm³ | 0.53 cm³ | 0.26 cm³ |

2  + +

|

11.7 cm³ | 5.85 cm³ | 1.95 cm³ | 0.97 cm³ | 0.73 cm³ | 0.49 cm³ | 0.24 cm³ |

3  + +

|

10.8 cm³ | 5.4 cm³ | 1.8 cm³ | - | 0.68 cm³ | 0.45 cm³ | 0.22 cm³ |

4  + +

|

9.9 cm³ | 4.95 cm³ | 1.65 cm³ | - | 0.41 cm³ | 0.21 cm³ | |

5  + +

|

9 cm³ | 4.5 cm³ | 1.5 cm³ | - | 0.38 cm³ | 0.19 cm³ | |

6  + +

|

8.1 cm³ | 4.05 cm³ | 1.35 cm³ | - | 0.34 cm³ | 0.17 cm³ | |

*The circlip must always be added on top of the washers

REMOTE INSTALLATION DISTANCES

| TYPE OF INSTALLATION | MAXIMUM DISTANCE |

|---|---|

| Single point | 8m |

| Multipoint | 6m |

Specifications

Electric Specifications

| MEMOLUB® HPS | |

|---|---|

| Power Source | Battery |

| Voltage | 4.5V DC (3x1.5V DC AA) |

| Short circuit protection | Yes |

| Stroke duration | 8 seconds |

| Minimum stroke interval | 15 minutes |

Other Specifications

| MEMOLUB® HPS | |

|---|---|

| Temperature exposure range | -15°C to 50°C* |

| Connections | 1/4 BSP |

| Lubricants | Oil and Grease (up to NLGI #2 with an oil base between 100 and 460 cSt)** |

| Maximum Stroke Presure | 25 bar / 350 PSI |

* Batteries + lubricant adapted for low temperatures.

** For any other viscosity level please contact your local distributor.

INSTALLATION GUIDELINES

DIRECT INSTALLATION

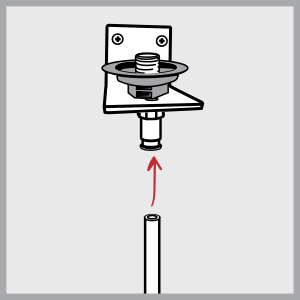

-

1

Prime lube point and remove nipple.

-

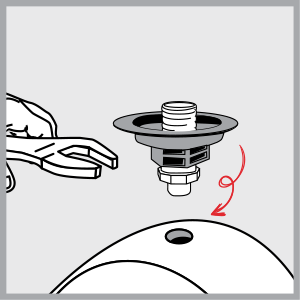

2

Install Memo on lube point.

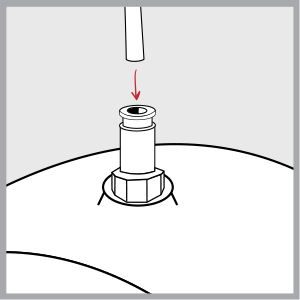

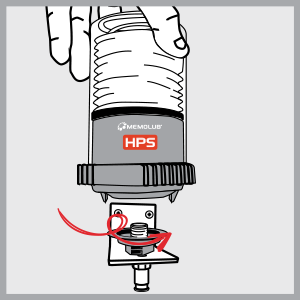

-

3

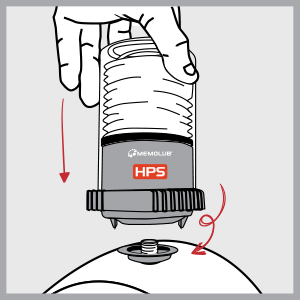

Install MEMOLUB® HPS on Memo.

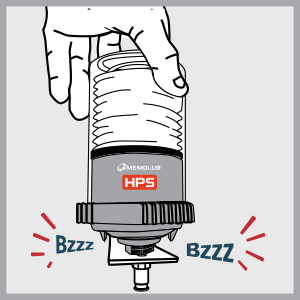

-

4

MEMOLUB® HPS works immediately.

REMOTE INSTALLATION

-

1

Prime lube point and remove nipple.

-

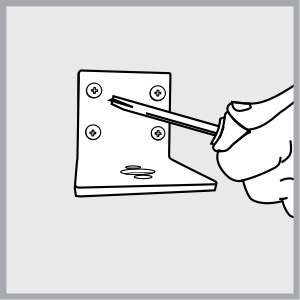

2

Secure the mounting bracket.

-

3

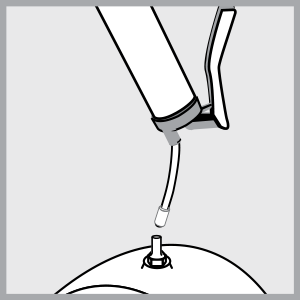

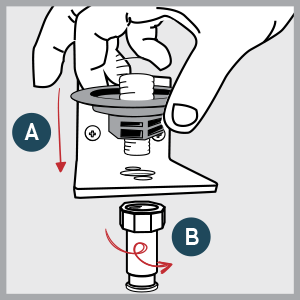

Install the base and F1/4 fitting on bracket using a strong threadlock.

-

4

Screw BSP 1/8 fitting on lube point.

-

5

Cut hose to required size.

-

6

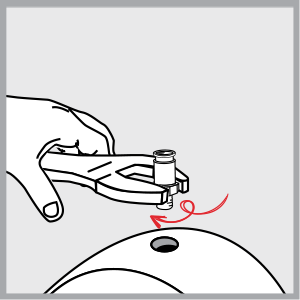

Insert hose into the bracket quick fitting.

-

7

Insert hose into the lube point quick fitting.

-

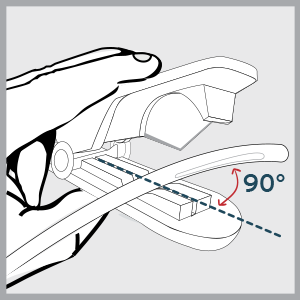

8

Install MEMOLUB® HPS on Memo.

-

9

MEMOLUB® HPS works immediately.

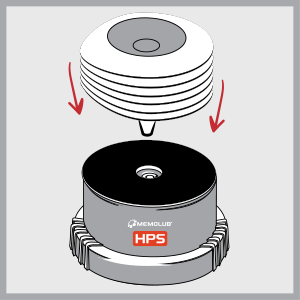

CARTRIDGE REPLACEMENT GUIDELINES

-

1

Open (fingers on ribs).

-

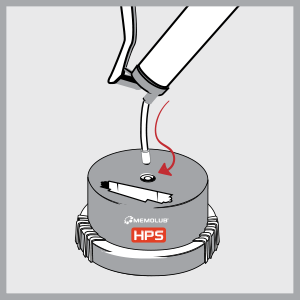

2

Prime MEMOLUB® HPS pump.

-

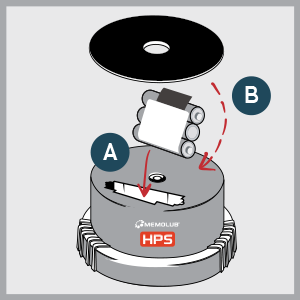

3

Insert new battery pack and seal. NOTE: the battery seal can be removed for 480cc cartridges.

-

4

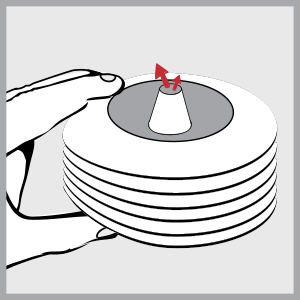

Squeeze air out of the cartridge.

-

5

Replace cartridge on MEMOLUB® HPS pump.

-

6

Close and lock (fingers on ribs).

FAQ

-

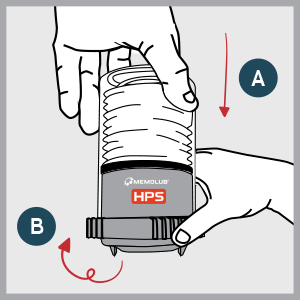

How can I test and/or check if MEMOLUB® HPS is functioning?

You can test and/or check whether MEMOLUB® HPS is working correctly at anytime by unscrewing MEMOLUB® from the MEMO by one turn and screwing it back. MEMOLUB® HPS will expulse once after being mounted to the MEMO.

If the environment is too noisy, unscrew MEMOLUB® from its MEMO and, push on one of the three switches at the bottom of the housing for a few seconds. MEMOLUB® will then make an expulsion to confirm that electronic, mechanical and batteries are ok.

Operate this operation three times pushing each switch at least once to ensure all three switches are operational and the complete gavage of the pump with the adequate lubricant. This operation has to be done with a cartridge inside the MEMOLUB® HPS.

-

What to do if my MEMOLUB® HPS automatic lubricator is not functioning?

Make a manual test of MEMOLUB® HPS by using a MEMO with the three rings in the ring-holder.

If MEMOLUB® HPS does not work, check the following:- Is there a battery pack in the MEMOLUB® and is it correctly inserted?

- Are the batteries ok? Use another battery pack to double-check.

- Are there one or more plastic rings inside the ring-holder? If not, no switch will be activated and MEMOLUB® HPS will not work. Make sure you insert them correctly as explained in the installation guidelines.

-

What to do when there is no lubricant coming out of my MEMOLUB® HPS?

If MEMOLUB® HPS does function, but no grease comes out of the automatic lubricator check the following:

- Is there a lubricant cartridge inside the MEMOLUB® HPS? If not, recharge the unit with a cartridge as described in the installation guidelines.

- Was the spring mounted correctly inside the transparent housing? If not, please mount it again as described in the installation guidelines.

- Is the pump of the MEMOLUB® HPS primed? If the cartridge of MEMOLUB® HPS was totally emptied before replacement, some air could have been sucked into the system and the pump would cavitate for a certain number of cycles. Place a grease handgun on the suction valve of the red housing and pump grease through the unit as explained in the installation guidelines.

-

What to do when the lubricant cartridge is not emptied correctly?

If MEMOLUB® HPS does function but the lubricant cartridge does not empty or not in the predicted timing there might be that of the following issues occurs:

- The piping is clogged: use a handgun to clear the pipes.

- One of the outlets of the distributor block has been voluntarily obstructed. Use bridging elements to reduce the number of outlets of a distributor block.

- The piping is damaged. Replace the piping.

- Counter pressure at the MEMOLUB® HPS outlet is higher than 20 bar: please respect the tubbing diameters, tubing lengths, the number of outlets per distribution block and the working temperatures. Also, use fittings with openings larger than 4mm (0.157").

- At working temperature, the base oil viscosity of the grease is higher than 10.000cSt. Please use low temperature lubricants.

-

What to do when the lubricant does not reach the lubrication point?

MEMOLUB® HPS does function and empties correctly, however no lubricant is reaching the lubrication point. Possible causes are:

- The piping might be damaged, please check and replace if necessary.

- A fitting is not correctly screwed or sealing is missing, please check and replace or add if necessary.

-

Does MEMOLUB® HPS needs specific maintenance?

MEMOLUB® does not require any specific maintenance. When used in humid or dusty atmospheres MEMOLUB® HPS can be cleaned with compressed air or a slightly humid rag. To clean MEMOLUB® HPS do not use solvents or plunge unit in any liquid. It is also possible to equip your MEMOLUB® HPS with a protection cover. For additional information, please contact your local MEMOLUB® dealer.

REGULATORY INFORMATION

| SYMBOL | DESCRIPTION |

|---|---|

|

|

This product is compliant with Directives 2006/42/EU (Machinery) and 2014/34/EU (Equipment in potentially explosives atmospheres - classification II 3 G for gases, II 3 D for dusts). The relevant Declaration of Conformity is available here. |

|

|

This product is compliant with UK regulations 2008 No. 1597 (Supply of Machinery) and 2016 No. 1107 (Equipment for use in potentially explosive atmospheres). The relevant Declaration of Conformity is available here. |

|

|

This product is compliant with customs union technical regulations TR CU 010/2011 (safety of machines and equipment) and TP TC 012/2011 (safety of equipment for use in explosive atmospheres). The relevant Declaration of Conformity is available here. |

|

|

The WEEE symbol is attached to the product in compliance with the EU directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE). It is intended to deter the improper disposal of this product and to promote reuse and recycling. |

|

|

The packaging material can be recycled. Please arrange for the environmental appropriate disposal of the packaging. |

|

|

This product is compliant with EN IEC 600790-15 (nC IIC T6 Gc) |

|

|

This product is compliant with EN IEC 600790-31 (tc IIIC T85°C) |

Memolub® HPS

- Reusable autonomous single & multi-point lubrication system.

- Battery powered.

- 350psi (25 bar) ejection pressure.

- Up to 12 outlets.

- Remote installation up to 40 feet (12 m).

- 52 Settings.