- Do not open the housing: loaded spring

- Hold MEMOLUB® down during manual checks

- Leq <70 dB

- Use MEMOLUB® only for greasing machinery

- Use only lubricant cartridges and batteries recommended by the manufacturer

Memolub® PLCD KNOWLEDGE BASE

Dimensions

Standard

120cc I 4oz

Mega

240cc I 8.1oz

Giga

480cc I 16.2oz

OIL R-500

500cc I 16.9oz

Precautions

INSIDE THE BOX

MEMOLUB® PLCD Pump

MEMOLUB® Housing Kit

MEMOLUB® PLCD Memo Kit

Settings & Installation

REMOTE INSTALLATION DISTANCES

| TYPE OF INSTALLATION | MAXIMUM DISTANCE |

|---|---|

| Single point | 10m |

| Multipoint with 2 outlets | 6m |

| Multipoint with 4 outlets | 6m |

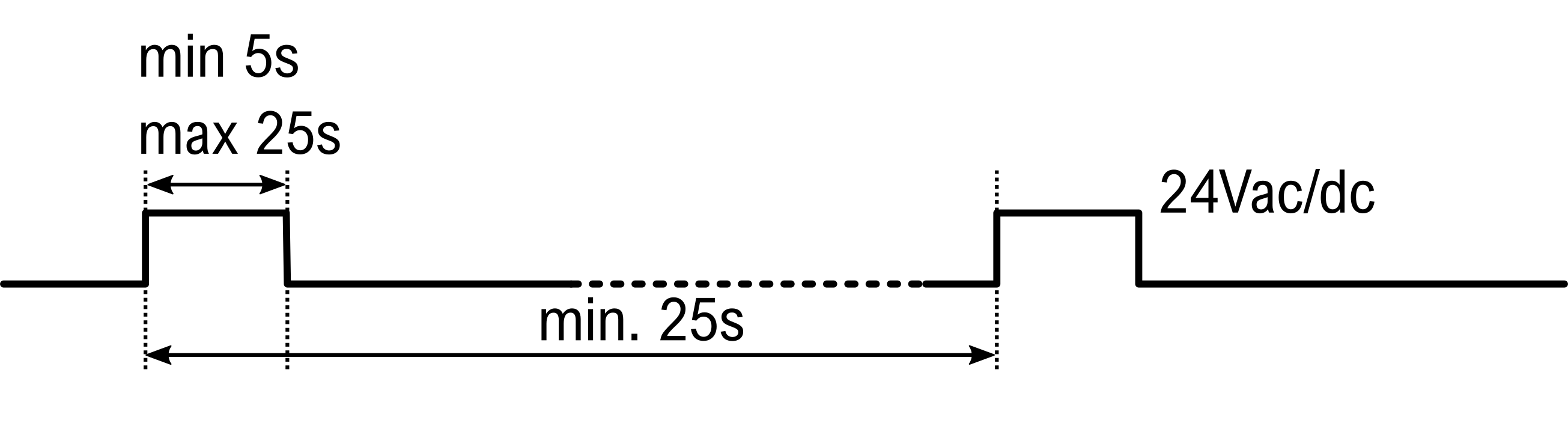

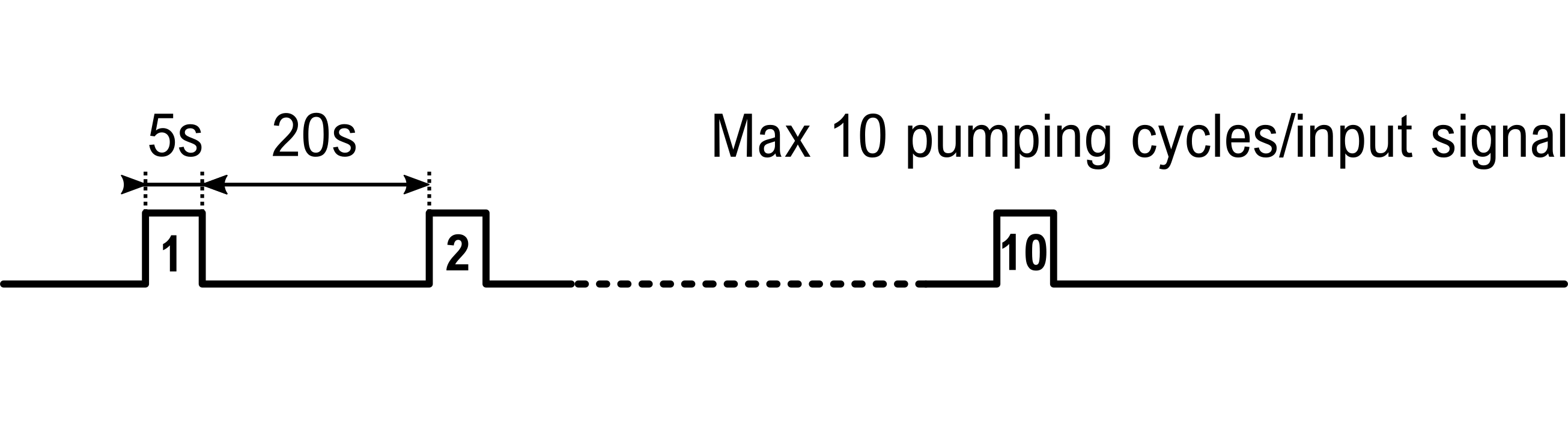

INTERMITTENT MODE

| DESCRIPTION | SIGNAL |

|---|---|

| INPUT SIGNAL (FROM CUSTOMER PLC/TIMER) |

|

| MOTOR DRIVE |

|

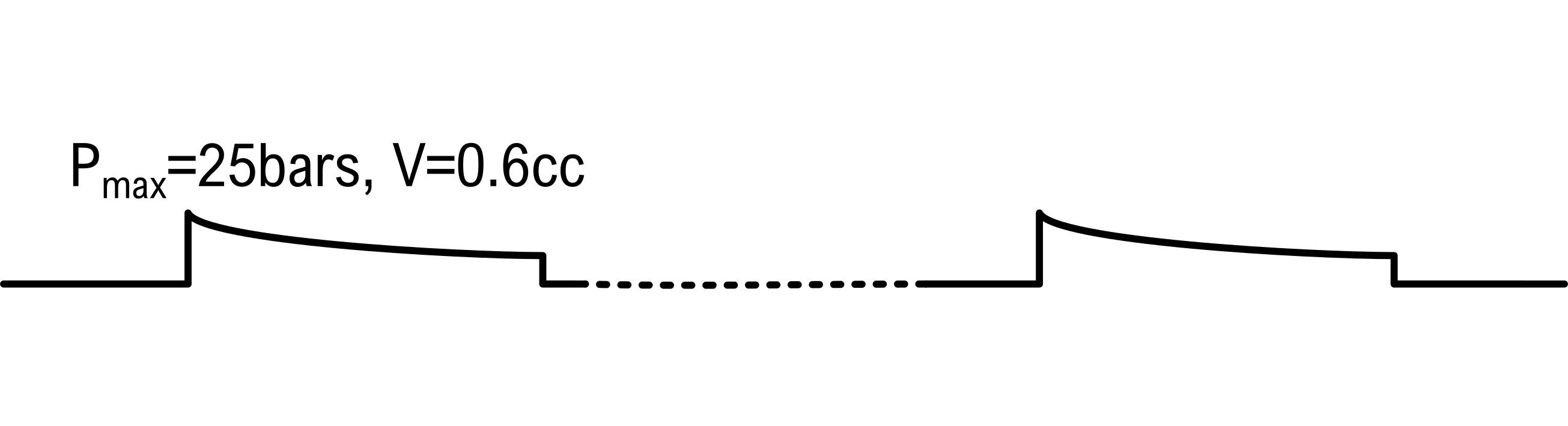

| PUMP OUTLET (TO LUBRICATION) |

|

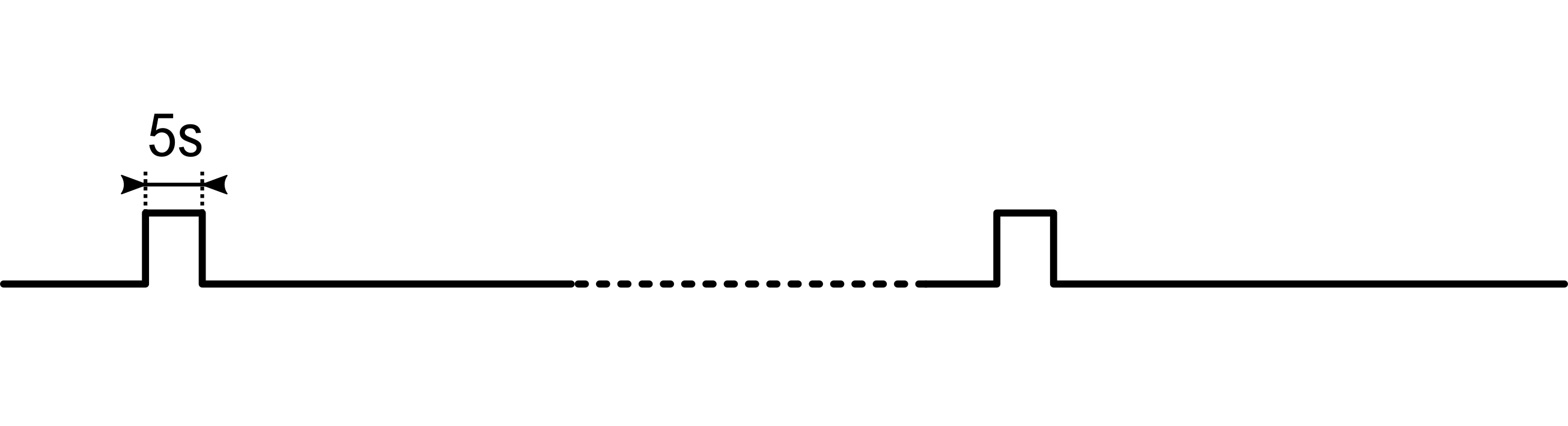

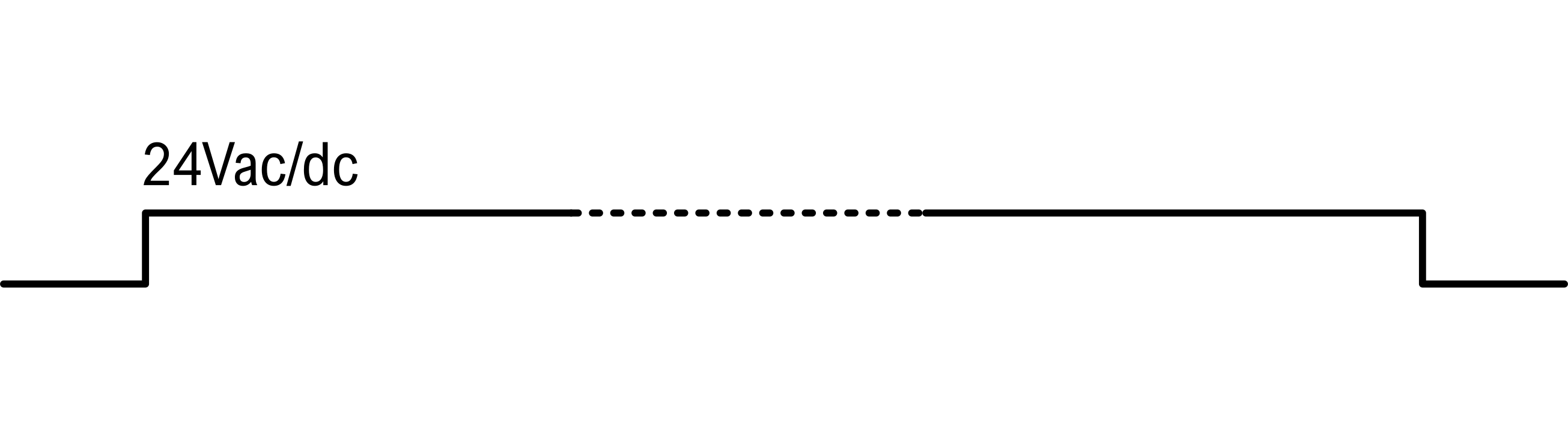

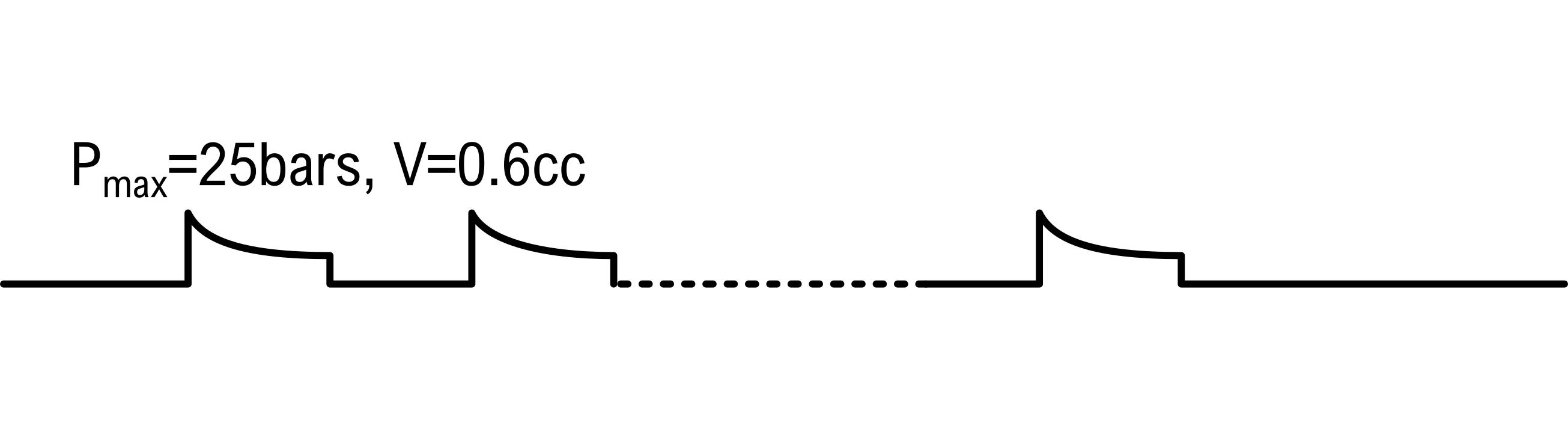

CONTINUOUS MODE

| DESCRIPTION | SIGNAL |

|---|---|

| INPUT SIGNAL (FROM CUSTOMER PLC/TIMER) |

|

| MOTOR DRIVE |

|

| PUMP OUTLET (TO LUBRICATION) |

|

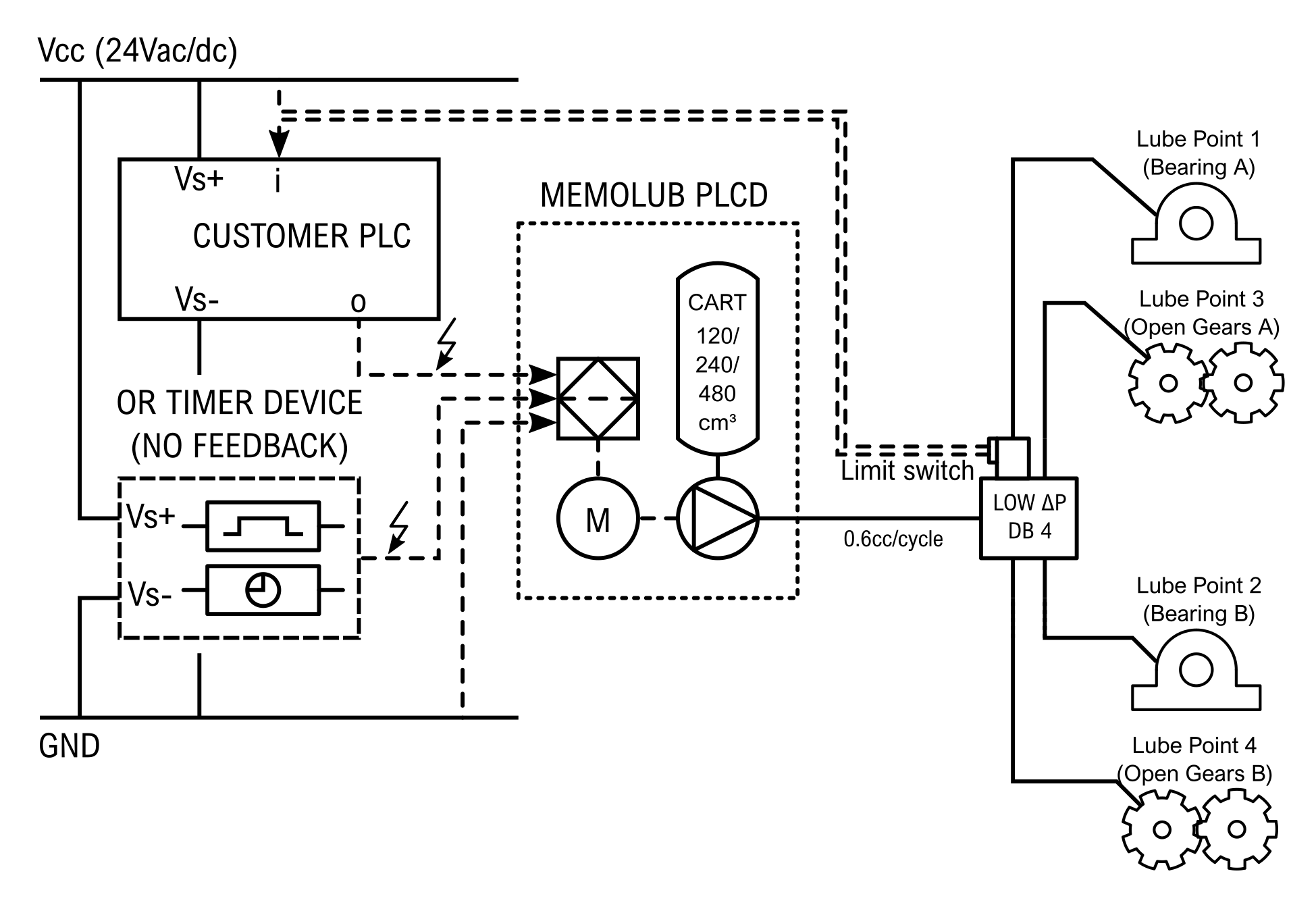

WIRING EXAMPLE

Here you have a wiring example with feedback from limit switch. For other examples please get in touch with your local distributor.

Specifications

Electrical Specifications

| MEMOLUB® PLCD | |

|---|---|

| Power Source | External Power Supply (min 15W - 0.6A) |

| Voltage | 24V DC |

| Cable type | VTLB RD H03VV-F 2x0,75mm² (200mm) |

| Short circuit protection | Yes |

| Stroke duration | 5 seconds |

| Minimum stroke interval | 20 seconds* |

* This time is given for low viscosity oils only. We recommend a minimum time interval of 15 minutes for greases. Please contact your local distributor for detailed information.

Other Specifications

| MEMOLUB® PLCD | |

|---|---|

| Temperature exposure range | -15°C to 50°C* |

| Connections | 1/4 BSP |

| Lubricants | Oil and Grease (up to NLGI #2 with an oil base between 100 and 460 cSt)** |

| Maximum Stroke Presure | 25 bar / 350 PSI |

* Lubricant adapted for low temperatures.

** For any other viscosity level please contact your local distributor.

INSTALLATION GUIDELINES

DIRECT INSTALLATION

-

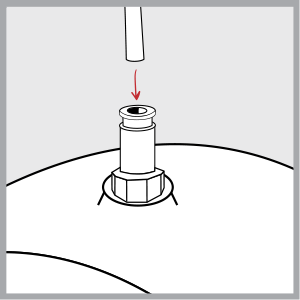

1

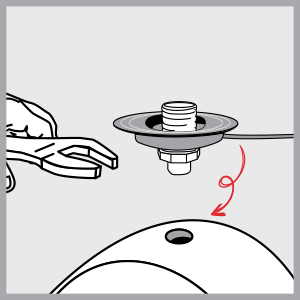

Prime lube point and remove nipple.

-

2

Install PLCD Memo on lube point using threadlocker (BSP 1/4).

-

3

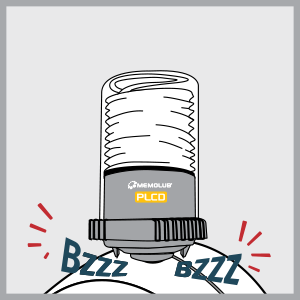

Install MEMOLUB® PLCD on Memo.

-

4

MEMOLUB® PLCD works immediately when triggered by PLC output.

REMOTE INSTALLATION

-

1

Prime lube point and remove nipple.

-

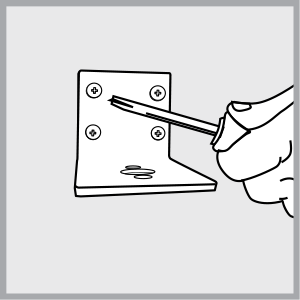

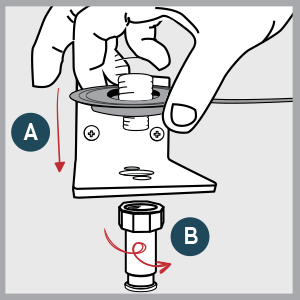

2

Secure the mounting bracket.

-

3

Install PLCD Memo and F1/4 fitting on bracket using a strong threadlock. Connect the MEMOLUB® PLCD cable to the PLC output.

-

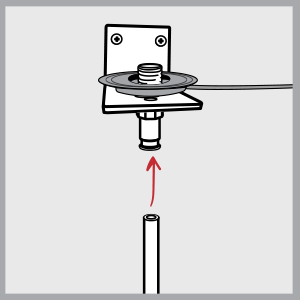

4

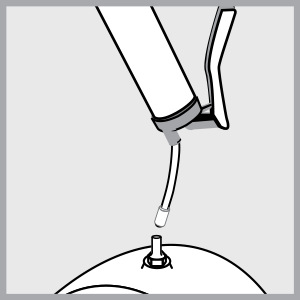

Screw BSP 1/8 fitting on lube point.

-

5

Cut hose to required size.

-

6

Insert hose into PLCD Memo's quick fitting.

-

7

Insert hose into lube point's quick fitting.

-

8

Install MEMOLUB® PLCD on PLCD Memo.

-

9

MEMOLUB® PLCD works immediately when triggered by PLC output.

CARTRIDGE REPLACEMENT GUIDELINES

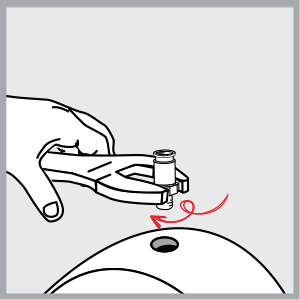

-

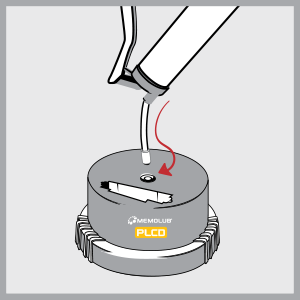

1

Open (fingers on ribs).

-

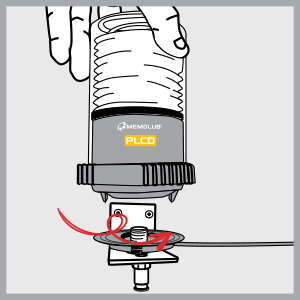

2

Prime the MEMOLUB® PLCD pump.

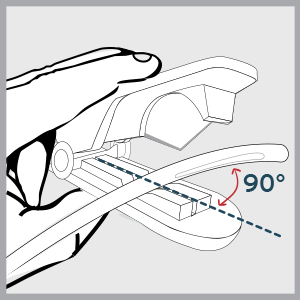

-

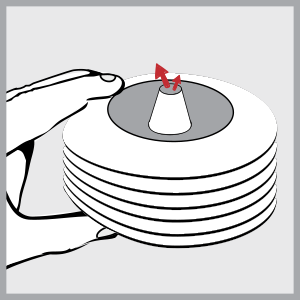

3

Squeeze the cartridge to evacuate air in the cartridge

-

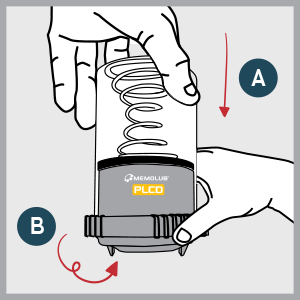

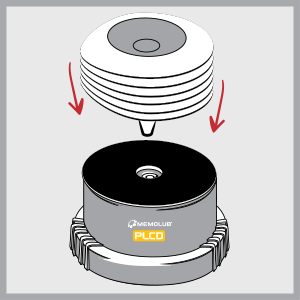

4

Replace the cartridge on the MEMOLUB® PLCD pump. NOTE: the battery seal can be removed for 480cc cartridges.

-

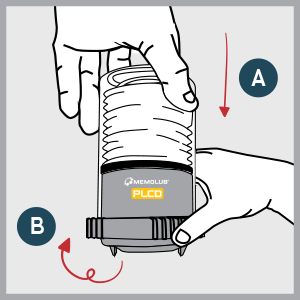

5

Close and lock (fingers on ribs).

FAQ

-

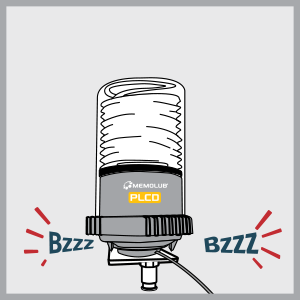

How can I test and/or check if MEMOLUB® PLCD is functioning?

You can test and/or check whether MEMOLUB® PLCD is working correctly at anytime by powering it OFF and ON again from the PLC. MEMOLUB® PLCD will then expulse once.

This operation has to be done with a cartridge inside the MEMOLUB® PLCD.

-

What to do if my MEMOLUB® PLCD automatic lubricator is not functioning?

Make a manual test of MEMOLUB® PLCD by using a MEMO with the three rings in the ring-holder.

If MEMOLUB® PLCD does not work, check the following:- Is the power supply ON?

- Does the power supply have the right ampliture (24V AC/DC) ?

- Is there any discontinuity in the wiring?

- Are there two brass rings inside the ring-holder? If not, no current can feed MEMOLUB® PLCD and this latter will not work. Make sure you insert them correctly as explained in the installation guidelines.

-

What to do when there is no lubricant coming out of my MEMOLUB® PLCD?

If MEMOLUB® PLCD does function, but no grease comes out of the automatic lubricator check the following:

- Is there a lubricant cartridge inside the MEMOLUB® PLCD? If not, recharge the unit with a cartridge as described in the installation guidelines.

- Was the spring mounted correctly inside the transparent housing? If not, please mount it again as described in the installation guidelines.

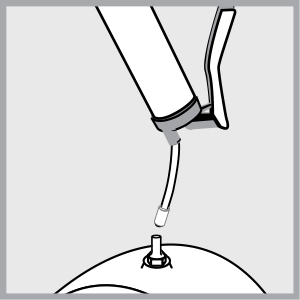

- Is the pump of the MEMOLUB® PLCD primed? If the cartridge of MEMOLUB® PLCD was totally emptied before replacement, some air could have been sucked into the system and the pump would cavitate for a certain number of cycles. Place a grease handgun on the suction valve of the red housing and pump grease through the unit as explained in the installation guidelines.

-

What to do when the lubricant cartridge is not emptied correctly?

If MEMOLUB® PLCD does function but the lubricant cartridge does not empty or not in the predicted timing there might be that of the following issues occurs:

- The piping is clogged: use a handgun to clear the pipes.

- One of the outlets of the distributor block has been voluntarily obstructed. Use bridging elements to reduce the number of outlets of a distributor block.

- The piping is damaged. Replace the piping.

- Counter pressure at the MEMOLUB® PLCD outlet is higher than 13 bar: please respect the tubbing diameters, tubing lengths, the number of outlets per distribution block and the working temperatures. Also, use fittings with openings larger than 4mm (0.157").

- At working temperature, the base oil viscosity of the grease is higher than 10.000cSt. Please use low temperature lubricants.

-

What to do when the lubricant does not reach the lubrication point?

MEMOLUB® PLCD does function and empties correctly, however no lubricant is reaching the lubrication point. Possible causes are:

- The piping might be damaged, please check and replace if necessary.

- A fitting is not correctly screwed or sealing is missing, please check and replace or add if necessary.

-

Does MEMOLUB® PLCD needs specific maintenance?

MEMOLUB® does not require any specific maintenance. When used in humid or dusty atmospheres MEMOLUB® PLCD can be cleaned with compressed air or a slightly humid rag. To clean MEMOLUB® PLCD do not use solvents or plunge unit in any liquid. It is also possible to equip your MEMOLUB® PLCD with a protection cover. For additional information, please contact your local MEMOLUB® dealer.

REGULATORY INFORMATION

| SYMBOL | DESCRIPTION |

|---|---|

|

|

This product is compliant with Directives 2006/42/EC (Machinery). The relevant Declaration of Conformity is available here. |

|

|

This product is compliant with UK regulations 2008 No. 1597 (Supply of Machinery). The relevant Declaration of Conformity is available here. |

|

|

This product is compliant with customs union technical regulation TR CU 010/2011 (safety of machines and equipment). The relevant Declaration of Conformity is available here. |

|

|

The WEEE symbol is attached to the product in compliance with the EU directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE). It is intended to deter the improper disposal of this product and to promote reuse and recycling. |

|

|

The packaging material can be recycled. Please arrange for the environmental appropriate disposal of the packaging. |

Memolub® PLCD

- Reusable single & multi-point lubrication system.

- 24V powered.

- 140psi (25 bar) ejection pressure.

- Up to 12 outlets.

- Remote installation up to 40 feet (12 m).

- PLC driven settings.

- Easy to incorporate in closed-loop feedback systems.