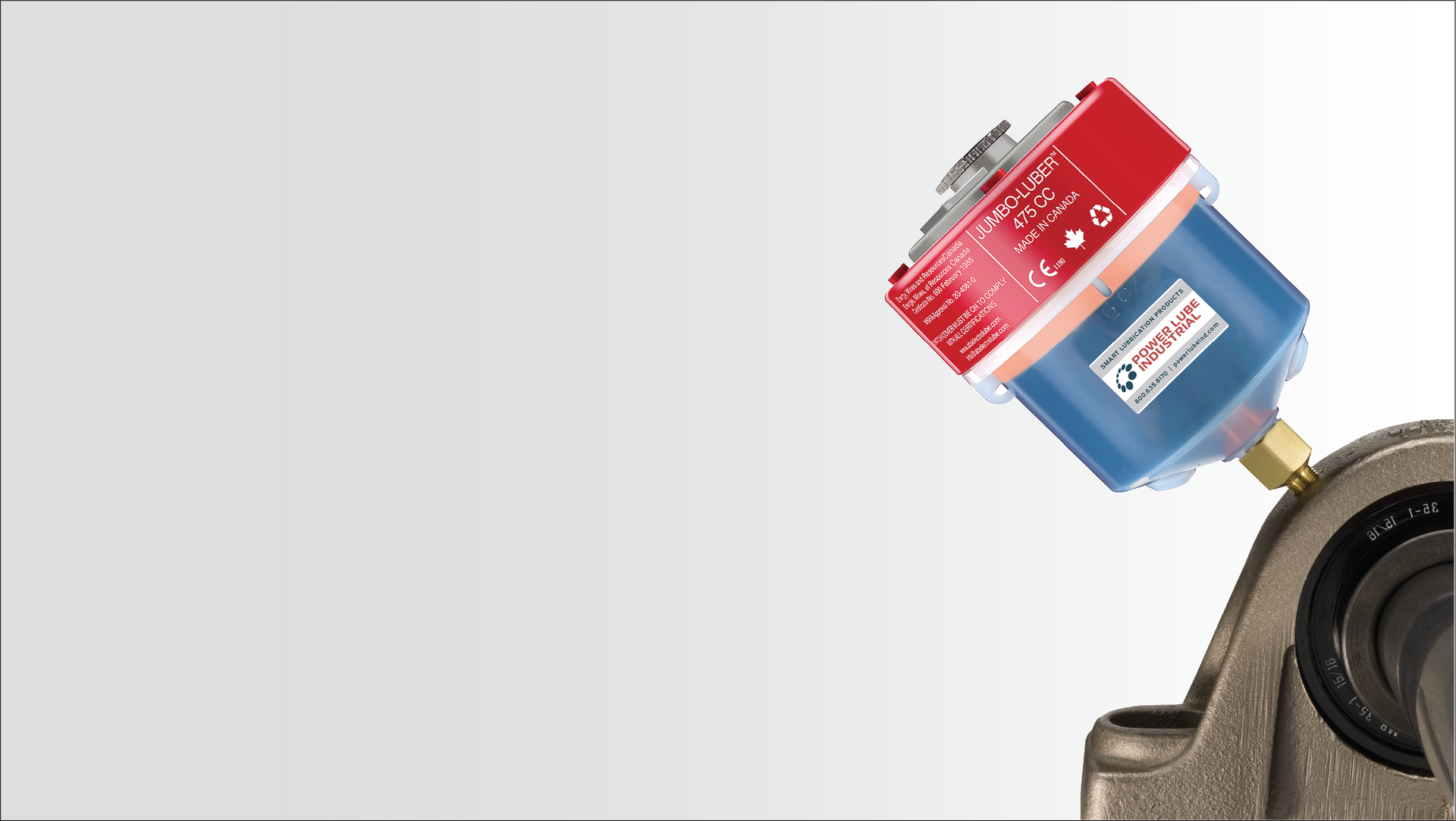

Electro-Chemical single point automatic lubricator.

The classic ELECTRO-LUBERTM was developed in 1982. The ELECTRO- LUBERTM uses an electro-chemical reactor cell which converts electrical energy into safe, inert nitrogen gas. The gas is trapped in a hermetically sealed bellows type gas chamber. ATS Electro-Lube was the first company to use this self-contained automatic lubrication technology; as the gas is produced an internal pressure builds up in the bellows and is applied against the orange piston. The piston then forces the lubricant out of the cylinder and into the point of lubrication. The unit can empty between 15 days to 1 year depending on the setting of the simple user- programmable DIP switch. The selection can be changed or turned off at any time.

- Pre-filled with any of our 200 stock greases or oils.

- Translucent reservoir to monitor lubricant level inside.

- Visible blip light provides confirmation that the unit is operating.

- Approved for all explosive environments.

- Easily turn On or Off any of the “15 days to 1 year” output settings

- Stock models are available in 125cc & 475cc. (60cc & 250cc available on request)

The original ELECTRO-LUBER™ uses time selector switches to activate a reactor cell in which an electro-chemical reaction generates safe, inert nitrogen gas.

The gas is contained in a hermetically sealed expandable bellows.

The expanding bellows applies pressure against a piston, and the resulting movement of the piston forces the lubricant out of the lubricant reservoir and into the point of lubrication.

The unit can empty from between 15 days to one year and can be changed or turned off at any time.